Nitro Engine Tuning Tips

Following the nitro engine tuning tips outlined on this page will not only extend the life of your engine, but they will solve most of your problems getting your engine to run correctly.

Your engine giving you fits? Let us help you get'er straightened out! |

Anyone who's ever messed with a glow engine can tell you that these little guys are finicky to say the least.

It's absolutely no fun when you've tried everything you could possibly imagine and she just won't run right. I've been there an done that.

If your engine is still giving you fits after you've exhausted all the tips on this page, feel fry to explain your problem here and maybe we can help you get'er straightened out.

Why Proper Tuning is So Critical

Before getting into specific nitro engine tuning tips, it's important for you to understand why it is so critical that your nitro rc engine be tuned correctly.

An automobile engine has a radiator and water pump. The water is pumped through the engine block to remove heat from the engine. The water then goes through a radiator (heat exchanger) where a fan passes air through the radiator to cool the water.

Unlike a glow engine, they also have a lubrication system. The oil is pumped from the oil pan to the engine to lubricate all of the working parts. The lubrication greatly reduces heat and wear from friction.

Without either the cooling or lubrication system the engine would very quickly become so hot that the internal parts would literally begin to melt, ruining the engine.

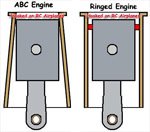

Never Run Engine Lean!The single most important nitro engine tuning tip I can give you is to avoid running your engine lean! It is just as critical for a glow engine to have adequate lubrication and cooling as it is for an automobile engine. Some of the heat from a nitro-powered engine is removed by air from the propeller moving across the fins on the engine's head. |

|

However, this is not nearly enough cooling to keep the engine from overheating. For this reason the fuel in a glow engine acts as a coolant to remove the heat from the engine. All glow fuels have a certain content of oil which lubricates the parts. By adjusting the high-speed needle valve you are controlling how much coolant and lubrication the engine is getting. |

Running an engine too lean will destroy your engine just a quickly as driving your car without oil or with a busted radiator hose. It is vitally important that you NEVER under any circumstances run your engine lean. The engine should be adjusted slightly rich at all times.

Keep in mind that the nitro engine tuning tips provided here are only guidelines for tuning your engine. Please read and follow the directions that came with your engine for adjusting the carburetor.

Adjusting the Needles

Every nitro-powered engine has both a high-speed needle valve and a low-speed needle valve.

The high-speed needle valve controls the amount of fuel that enters the carburetor when the engine is running fast. The low-speed needle valve controls the amount of fuel entering the carburetor when the engine is at idle.

You always want to set the high-speed needle valve first because the low-speed needle valve position will be dependent on where the high-speed needle is set.

A very important nitro engine tuning tip is to make sure you learn to tell when your engine is getting too much fuel (too rich) or when it is not getting enough fuel (too lean).

Setting The High-Speed Needle

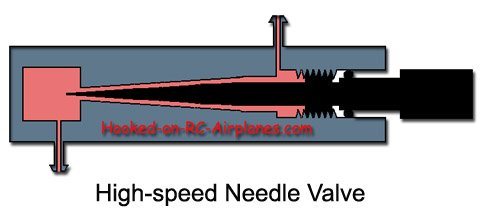

A needle valve consists of a tapered "needle" that seats against a tapered journal. Needle valves are used where very fine control of flow rates is necessary.

Some nitro powered engines have the high speed needle valve mounted right to the carburetor. This is dangerous because you have to adjust the engine while it is running, and the carburetor is darn close to the propeller.

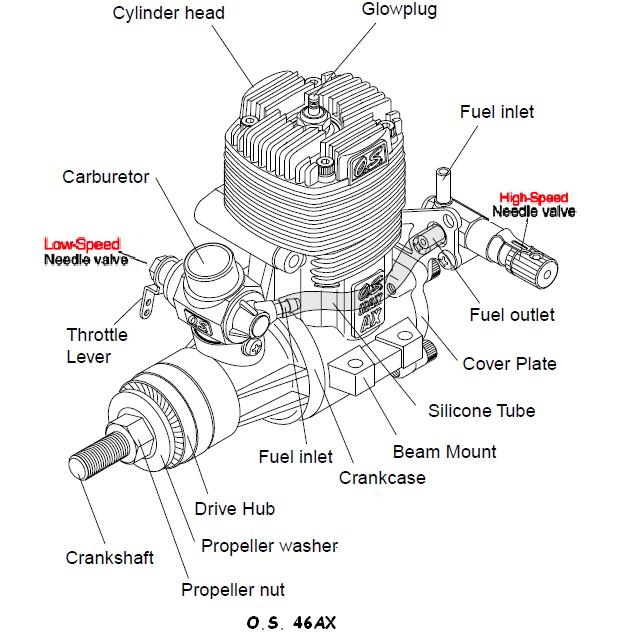

Most nitro engines have the high speed valve mounted behind the engine and is connected to the carburetor by a length of silicon fuel tubing. You can see this on the diagram above of the O.S. 46 AX engine.

Setting the high-speed needle valve is fairly simple. Run the engine at full throttle and observe how it reacts. If it is stumbling, not firing consistently, or producing excessive smoke then it is running too rich.

As you close the high-speed needle valve, the engine will begin to run smoother and the RPMs will rise. The engine will continue to speed up as you close the needle valve until you pass the optimal fuel setting.

At this point the engine will begin to slow down as you decrease the fuel going to the engine as it is now too lean. When this happens, immediately open the needle valve a couple of clicks! If you run the engine at a lean setting for more than a few seconds it will damage your engine.

The pinch test is probably one of the best nitro engine tuning tips than I can offer. When the engine is at full throttle, simply pinch the fuel line feeding the carburetor for a brief second.

It's best to pinch the fuel line that connects the carburetor to the high-speed needle valve. This would be the line labeled "Silicone Tube" in the above drawing. If you pinch the fuel line before the high speed needle it will take the engine longer to react.

If the engine is running rich, the RPMs will increase slightly before the engine sags. If the engine is lean, the RPMs will immediately decrease.

The high-speed needle valve should always be slightly rich. Slightly rich is good for your engine. Slightly lean will destroy your engine!

The engine will lean out while flying your airplane due to the emptying of the fuel tank. You will need to compensate for this by setting the engine slightly rich on the ground.

If in doubt, always err on the side of being too rich. Your engine will last longer and there will be less of a chance of your engine stopping in mid flight.

I hope these nitro engine tuning tips help you get the most out of your engine. If you're still having problems after following these tips, by all means explain your problem below so we can help you get off the bench and into the air!

Adjusting Four-Stroke High Speed Needle

Because the tone of a 4-stroke is so much lower than a 2-stroke, it is very difficult to tune the engine by listing to the engine speed. A tachometer is a necessity for tuning a 4stroke engine.

This leads to my next nitro engine tuning tip. If you have a four-stroke, buy a tachometer!

Adjusting your engine without a tachometer is very difficult and you take the chance of running your engine lean and ruining it. Investing in a good tachometer will extend the life of your engine by allowing you to properly adjust the fuel settings.

Setting the high-speed needle for a 4-stroke is basically the same as it is for a 2-stroke. The only difference is that you watch the tachometer as you adjust the needles instead of listening to the engine.

|

Tips on Breaking in your Engine |

Starting with a definite rich setting, slowly close the needle valve and watch the RPMs rise. Watch for the peak at which the engine stops speeding up and begins to slow down. Note what the tachometer indicates at this point, then open the needle valve slowly until the RPMs are about 200 less than the peak rpm. This will set the engine slightly rich. |

Another nitro engine tuning tip is to hold the airplane vertically with the nose up and run the engine at full throttle. Be very careful while holding on to the airplane tightly. It is best if you can have a friend hold the airplane while you operate the transmitter, or vice versa.

If the engine runs steady or slightly increases in rpm as you raise your airplane to the vertical position, you are in good shape. If the engine slows down at all then the setting is too lean so you need to open the high-speed needle a little bit and try again.

Repeat this process until the engine runs steady with no sagging for at least 30 seconds at full throttle while holding it vertically.

Setting the Low Speed Needle

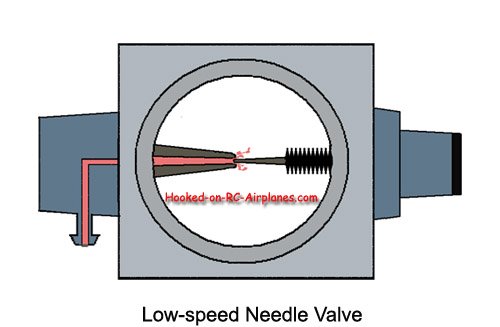

After you are satisfied with the setting of the high-speed needle, it is time to adjust the low-speed needle valve. This valve not only controls the fuel/air mixture when the engine is idling, but also controls the fuel/air mixture as the engine transitions from idle to full throttle.

It can sometimes be a little frustrating to get this setting just right so that the engine transitions smoothly from idle to full throttle without sputtering or dying.

The low-speed and high-speed needle valves work in conjunction with one another. When you adjust the low-speed needle valve it may be necessary to re-adjust the high-speed needle valve. Then of course, you may need to readjust the low-speed needle valve again. It is not difficult, but it does require some patience.

Most nitro engines have a needle valve for adjusting the idle, but there are a few that use an air bleed screw on the carburetor. It is important to know which one you have because turning in a needle valve leans the mixture while turning in an air bleed screw causes the engine to pull in more fuel making it run more rich.

Low-speed needle valves are very touchy. You only have to move them a hair to make a huge difference.

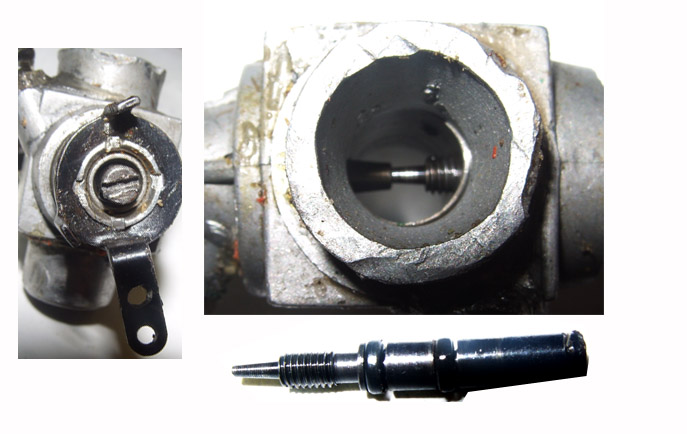

Most engines today have a low-speed needle valve. This is a little different than the high speed needle valve. The low speed needle valve is locate in the carburetor. This entire assembly seen in the picture above is commonly referred to as a "spray bar".

Above are some pictures of the spray bar assembly in an engine from my graveyard. Please excuse the condition of this carburetor, this engine has been buried in the dirt a couple of times. But this give you an idea of what the low-speed needle consists of.

Once your engine is warmed up, bring it to an idle. A lot of people want the engine to idle as slowly as possible, especially with 4-strokes because it sounds cool. But it is smarter to adjust the throttle linkage and throttle trim so that the engine idles as fast as you can get it without having enough thrust to pull the airplane forward while on the ground.

Just sit the airplane down on the ground and use the trim to adjust the throttle to the point were it is on the verge of moving the airplane. There is really no need to have a super slow idle speed that makes your airplane vulnerable for a dead stick landing. Well, except for the fact that it sounds really cool when a four-stroke practically goes silent when the pilot lets off the throttle...

When you are satisfied with the idle speed punch it to full throttle all at once. If the engine dies quickly the mixture is too lean so you need to slightly turn out the needle valve and try again.

If the engine sputters, coughs, and slowly dies then it is too rich and you need to very slightly turn the slow-speed needle in and try again.

Please follow this important nitro engine tuning tip of turning the slow-speed needle valve only a tiny amount each time. It will save you much time and frustration.

Once you have achieved a smooth transition from idle to full throttle, you need to double check the high-speed setting again. If it is still good then you are ready to go flying!

Sometimes adjusting the low-speed idle can mess up the high-speed setting. You may have to adjust the high-speed again. If this is the case, you also need to check/re-adjust the low-speed after re-adjusting the high-speed.

Many times you can get it pretty close the first go around. But

sometime engines can be stubborn and you have to keep fiddling with both the

high-speed and low-speed together until you are happy with it.

Having Engine Problems?

We've all had those days when our engines give us fits! We know how frustrating it is to spend more time tinkering with the engine than actually flying! And those dead stick landings get old fast!

If your engine is giving you fits, we'll get to the bottom of it one way or another! This is also the place to share the solutions to problems that have may plagued you in the past so that others may benefit!

You may find your answer by checking out what others have already asked.

See submissons from other visitors

Click below to see some of the problems, solutions, and general nitro engine tuning tips from other visitors.

OS 120 glow dies after a few minutes of smooth operation

Airplane Engine, OS 120 glow, start properly, idle ok, scream nice at high revolution, nose up test right.

I take off, a few laps with some aerobatic …

Factory settings OS 46

I have an OS46 engine and would like to know what the factory settings for both the Low and High speed needles are. The engine will start but not continue …

tuning problem with O.S. .91 FX

Have three of these engines. One, after many problems, blowing glow plugs, vibrating the head loose, vibrating the prop nut off, overheating and dying …

Frozen carburetor.

I'm trying to open and close the carburetor after it has been sitting for several years in the closet and as I try to open and close the carburetor with …

OS.46 fuel flow

I can blow through the exhaust tube and fuel runs through the fuel line, but once I connect it to the Carb fuel can't flow nor can I force it buy blowing …

Os 46 AX. will run when primed then die

Os 46 AX. I can cover the carb with my finger and it will prime and then start right up. But as soon as it runs through the prime it dies. I can see the …

Performance changes after a couple of minutes in the air

I have a vintage 20cc Super Tigre that has been rarely used since new. Getting correct idle and full throttle settings on the ground is difficult as the …

OSX - I believe it's a .40 or .46, sputters and raw fuel comes out of the muffler

I have an OS-X engine (an older one with both high speed and low speed needles. I believe it's a .40 or .46 engine. It sputters and slowly loses power …

Os52 reluctant to start, rpm drops then quits.

Hi, I have an OS52 surpass which will only start after LOTS of priming after which fuel pours from the carburettor. When the engine does start the rpm …

how to rework my old mccoy and fox 35 engines to operating conditions

I have several old mccoy and fox 35 engines that I want to refurbish and get running again for some new planes that I am building.

what tools and what …

fuel delivery issue

i have two glow planes with similar problems. air in the lines. i removed cleaned the tanks. replaced fuel lines. i can blow through the exhaust line and …

OS65 not reaching high RPM

I have an OS65, and it just does not seem to reach a high RPM on max throttle. Tried adjusting the mixture screw both ways but either the engine has no …

OS 25 Starts Up Nicely then dies and will not start again.

I have an os 25 max fs. Starts nicely and runs for a few seconds very good. Then when I throttle down it will die and I CANNOT get it to start again. …

OS 55 Ejected GlowPlugs

I have been having a few starting and running issues with my OS 55 AX. Today it spat out three Glow plugs.

Does anyone know why?

Old Enya 40 4c

Idle and mid speed running is a little choppy and bouncy, but at full throttle it surges a ton. The high speed needle Dosent change it at all. I can keep …

Leo .40 engine running problems

I have a leo .40 engine and its lucky if its had 20 mins running time in 7 years. I have aquired this project from my dad to kill time however i can get …

Low end Mixture meter setting on Thunder Tiger 50

I have a 50 size heli with super tiger 50 engine. Getting it to run is just giving me fits. I have set from the closed position 3 turns out for the high …

Asp 75 wont prime or hold a prime

I have a ASP 75 that's been setting for about 10 years , I put it on my bench test stand tried to get it to prime and hold a prime, it's not pulling up …

OS AX .46 Kicks/Whacks at idle

I have have an OS .46AX having quite some running hours. On medium and high speed the engine runs smoothly (smooth rpm), but on idle it is sort of kicking/whacks. …

OS 46 LA dies when climbing or verticle poistion

Well my OS 46 LA runs as close to perfect as it gets on the ground. Idle is great, slow to fast speed is great, and she is just between rich and lean right …

TT 46 Pro Engine wont tune

I've messed with the low end needle of my TT 46 Pro Engine have got it so when I pinch the line it rises barley and then goes back to a nice idle.

But …

ASP46S 2 stroke surges at full throttle

Engine surges when on full throttle after 5-6 seconds.

Idles perfectly

runs up to full throttle perfectly

10%nitro

mix of castor/synthetic

No7 Modeltechnics …

OS-46 AX Engine Dies When Airplane is Nose Down

Hello, I have an OS-46 ax mounted in a world models skyraider. It runs fine nose up , upside down , sideways and level flight but as soon as I point the …

Great website

Just a quick message to say thanks for such an informative website.

I was literally tearing my hair out with an ASP 4 stroke, but with the information …

Evolution 52NX Dies with Dirt in Fuel Line

I start my engine and it'll run good for a few minutes then it will die. With close inspection while running I noticed carbon passing through the fuel …

Evo 46 Engine Just Quits

I have a Evo .46 engine...

I start it up but when I give it throttle it just sputters, so I do some adjustments and iv got it up to maybe half throttle …

going rich in the air asp52

I can set the mixture correctly take off and when flying it will go rich. I land lean it out take off again and the thing goes lean and quits, I can't …

ASP .61 No Compression

My ASP .61 was running smooth and at a certain point in time I heard a strange noise inside the engine and it stopped running.

I tried to turn the …

OS 46 AX 2 Idle speed drops

If I am at full throttle 12000 rpm and lower it to low throttle the revs drop quickly to about 3000 rpm and then drops a further 500-600 rpm over about …

Sullivan Gas tank cap

Once all hardware is installed in gas cap and placed on tank, there is no seal and just falls out.

I'ts like the cap was too small to begin with and …

OS 1.08 BX-1 Keeps starting backwards

My OS 1.08 BX-1 Keeps starting backwards. 6/7 times it will start backwards instead of the right direction.

When it finally starts the correct way …

ASP 75 Keeps Running

My ASP 75the engine starts and runs fine. But when I close the throttle it keep on running.

It has two needles. The main one where the fuel goes in …

OS 46 AX Starting up proplems

Why do I always have to choke my OS 46 AX to get it started, by opening the throttle full and turn the prop for about 4 times while I block the air vent …

high speed needle does not change rpm

High speed needle does not change amount of fuel entering carb nor change rpm. At high throtle I get around 14,000 rpm. When I turn needle out to increase …

ASP 55 S52 factory low speed needle setting

I screwed up factory low speed needle setting. Can anyone tell me at what point to set the screw to begin trying to set the low end?

ASP .91 2 Stroke will not start

It will not start, and I have no idea what the optimum needle settings are because I cannot find a manual

Magnum 52 Engine Will Not Stay Tuned

I have a Magnum .52 and I have been having trouble with the engine not holding the settings. I get it running like a champ the take it to the field just …

ASP 108 Engine Transition Problem

I have been tuning this engine for a week and cannot get the full throttle to idle transition just right.

It seems to holds RPM's through the mid range …

In flight, engine dies when set back to idle?

Hi, I have a magnum 46xls engine and runs perfect on the ground, and runs well in flight But when set back to idle for landing approach it DIES almost …

Air Bubbles in Fuel Tank?

I have a new os .75 AX.

I have constant air bubbles in the fuel line.

I have checked air lines and tank and everything looks good as far as I can tell. …

Plane moves when 91 Magnum 4-stroke at Idle

I have read this forum and thank you for your knowledge. When I read the section about setting the low speed idle it says to "just set the airplane on …

Engine Dies at Idle when Glo Starter is Removed

When I remove the glow start from my 40 OZ MAX FP engine it dies.

If i open it to full throttle it runs nicely without the glo starter. As soon as I …

ASP .75 Tuning Issues

I have a problem keeping my SC ASP sc71/75 running. I was told it was a 71 , but cannot find a reference to that on the internet. I can only find an SC …

Evolution engine dies when running full throttle

I have Evolution Trainer Power System .46 engine that dies when running at full throttle.

Well actually, my first problem is that most of time this …

Engine stalls after 2-3 minutes of flight

I have an evolution 45 engine on an Alpha 40. I have aprox 3 hours max on the engine. The first three months I have been flying it, the engine has run …

OS 75 AX Engine Quits on T/O

After following the tuning tips in this article , the OS 75 AX still quits on T/O or after a short time in the air.

Any suggestions?

SC120FS won't run at high speed

The engine has run at full speed but no longer will. Fuel hasn't changed (another 120 ran on it since).

Problem first manifest in a climb and now on …

key that holds prop mounting plate on crank shaft Not rated yet

Had my ASP engine running not bad. Next thing I know the prop mounting plate came off. Discovered the little key that connects plate to crank was lost. …

65AX Factory Needle Settings Not rated yet

My 65AX "Mix control valve" not set right, the low speeed or "Mixture Control Valve" has to be reste to factory.

What are the factory settings?

…

More engine related pages...

Home > Glow Engine Basics > Nitro Engine Tuning Tips

Let’s Go Flying! |

|

5 Steps for Successful First Flight! When the RC bug bites, it bites hard! Control yourself my friend! Save yourself much time and money by following these five steps to success! |

Glow Engine Basics